R&D

R&D

Since 2017, we have been conducting research on the swift deterioration of nature, production, and lack of control over time. This has raised concerns about the future of humanity on Earth. Many industries have the potential to alleviate these concerns through dedicated efforts and proactive measures. It is believed that furniture manufacturers and designers in Turkey are not meeting the sufficient standards for sustainable furniture production. In this research, the aim was to examine the criteria related to sustainable furniture production in Turkey. The sub-objectives included assessing how designers adhere to these criteria during sustainable production, determining their level of implementation, identifying areas of non-compliance, and gauging their knowledge on the subject.

Turkey was chosen as the research field for this purpose. Designers and manufacturers working independently or within companies in Turkey were included in the study, utilizing surveys and observation methods. The research methodology involved both qualitative and quantitative approaches. Life cycle design, sustainable production certification criteria, and government initiatives were utilized to establish criteria for sustainable furniture production. The gathered data underwent thorough analysis. As a result of the study, sustainable furniture criteria were categorized into four main aspects: raw materials, production, usage, and post-usage disposal. These criteria were then presented to designers in the form of survey questions. The survey results indicated that furniture designers achieve a 54.67% compliance rate with sustainable furniture production. It is evident that swift and effective measures are needed to enhance sustainable furniture production. Expert opinions suggest a lack of sufficient government incentives in this regard. In the rapidly deteriorating world, it is crucial for authorities to take necessary actions.

The research revealed that along with incentives, training, and resource development, new implementation methods were necessary. Sustainable production needed to be implemented across all sectors. We understood that we could do something, albeit small, to mitigate the deteriorating environmental conditions within our expertise.

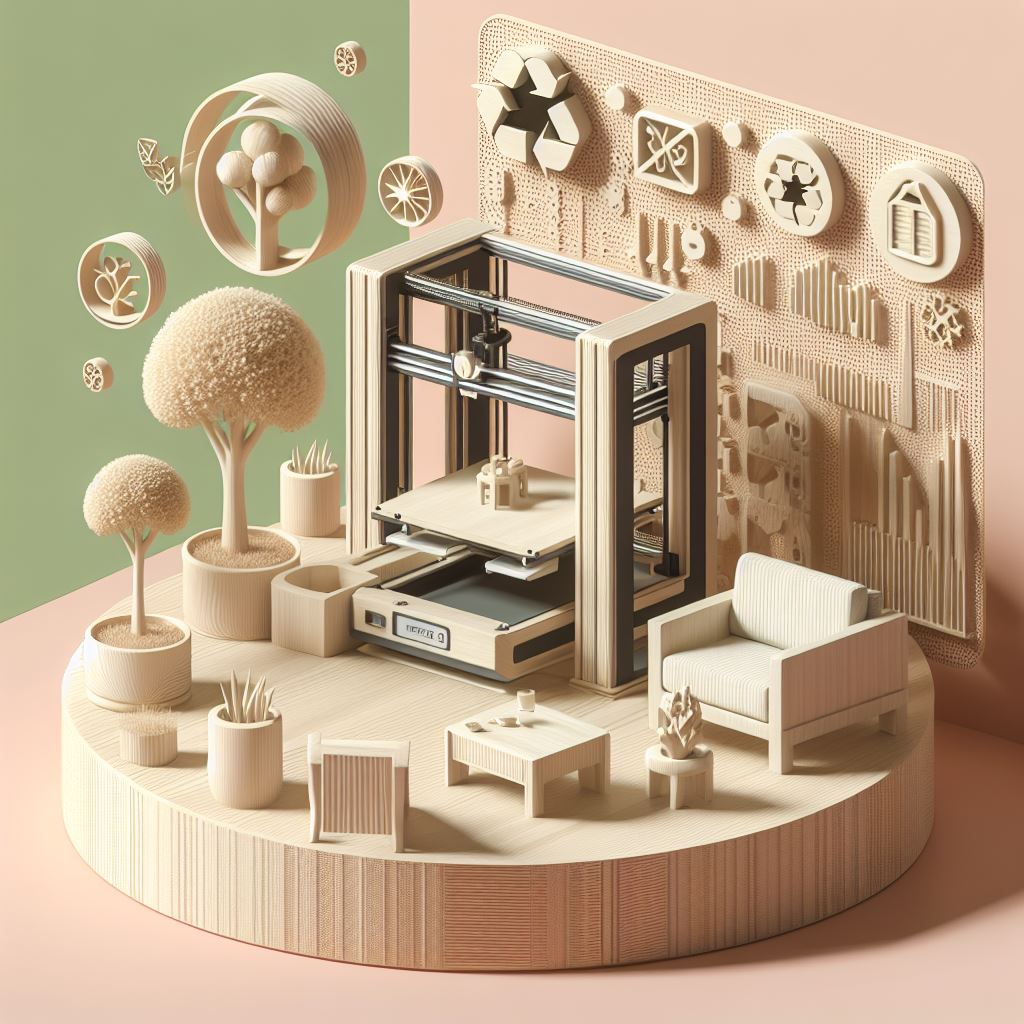

We took action. Traveling country to country, we followed evolving technology and examined new production methods on the international stage. We noticed a raw material that had emerged in recent years, indicating the foundation of a new system worldwide. We swiftly got to work. We faced challenges in Turkey due to the unavailability of necessary products, from the machine for our production line to equivalent raw materials. After months of research and analysis with our team, we confirmed that we could carry out this production in Turkey. While no one in Turkey could produce the entire machine, we found a company where we could import some parts and complete the rest locally. We reached out to international sources for the raw material, and our efforts to produce this material in Turkey are ongoing. Thus, by implementing this production system in the furniture industry and reducing our carbon footprint, we aim to decrease carbon emissions originating from Turkey by 90%.

We are now ready! Our machine, raw material, and team are prepared. We are eager to share the designs we have created with you. We invite all Turkish and international designers to join us and aim to expand globally with our designer-friendly applications. By setting an example for other sectors, we believe we can stop waste formation and carbon emissions.

Believe in yourself! We know you are tired of the question, 'How will you produce this?' and the limitations imposed by machines in the industry. We understand that you have faced challenges with the limited capabilities provided by the machines in the sector. We've been through these processes too!

Now, you can quickly learn the basic rules you need by watching our educational videos and become capable of designing for 3D printers.

When you need prototypes for your initial experiments, we can share 1/10 scale models from our small-scale 3D printers, helping you identify the strengths and weaknesses of your products. Over time, you will see your skills improving!

We will also evolve! We are examining all our shortcomings to predict the necessary training and experiencing the process ourselves. You can provide feedback on areas of improvement, contributing to our development!